A History of Corrugated Boxes

Ah, corrugated boxes. Where would we be without them?

Probably in a mess of papers, equipment and other miscellaneous consumables in desperate need of a place to belong. Creating perfect-fitting, customized packaging for any (and all) of your businesses needs is what the team at Covenant Packaging does best. Have you ever wondered how corrugated boxes came about to begin with? If so, you’re in the right place.

Fashionable Beginnings

Before there was corrugated cardboard, there was simply cardboard. Unlike its layered, durable cousin, cardboard is a single layer of stiff pasteboard. It was invented in England circa 1817 by the firm M. Treverton & Son. Though thin and simple, it was a precursor to the gold-standard product of today, which wasn’t created until several decades – and fashion changes – later.

Its genesis is actually in men’s fashion. English business partners Edward G. Healy and Edward E. Allen needed something to make top hats more durable and comfortable. Unable to find exactly what they needed, they did what so many others do in that very same precarious situation and created their own solution.

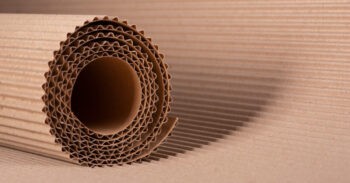

Using a simple machine, they hand fed paper through a device with two pleated rolls. The result was neatly fluted paper that was patented in 1856 as a hat lining material.

Now, more than 150 years later, their paper technology has evolved into four different types of corrugation that absolutely revolutionized global commerce. How? Let’s find out.

Small Mistake, Big Discovery

The English get credit for the material we use to create boxes. But when it comes to boxes themselves…accolades belong to America.

Robert Gair owned a printing and paper bag making company in the 1870s. One day, while working in his Brooklyn, New York factory, he serendipitously discovered the incredible versatility of corrugate when a job of his went awry.

He was cutting paper bags when a metal creasing ruler slipped. Instead of bending the corrugate, it actually cut through it. Gair quickly realized that by cutting and creasing at the same time, he was able to make boxes that could be used, flattened and reused again.

Today, corrugated cardboard is the only packing material that can be cut and folded into any shape, any size or any application that you need it for. That explains why more than 70% of businesses use it to package their consumer goods.

The Future of Corrugated

The advent of corrugated packaging rocked the modern commerce landscape. Since becoming approved for rail transport in 1903, it has only become more prolific.

Today, the industry has grown so tremendously that it now employs hundreds of thousands of people around the world, contributing more to the world economy than the film and music industries combined. Thankfully it is also as friendly to the earth as it is to businesses everywhere.

When used correctly, corrugated boxes can be reused 7 times before losing strength. When it has exhausted its functional life, some get creative and use it in gardens or for home projects. Others send it to be recycled.

According to the American Fiberbox Association, 100% of its material can be recycled, making it just as easy to talk about recycling corrugated as it is to actually do it. Every ton saves 700 gallons of water, 17 trees and 9 cubic years of landfill space. Multiply that by the millions of tons that are recycled each year and the environmental impact is huge.

Talk about hard work for such a simple, cost-effective solution!

In Closing

Corrugated boxes have only been around for a couple of hundred years, but has already managed to transform the way we do business around the world.

To see everything custom packaging can do for your business, give us a call today. One of our packaging professionals will be happy to guide you through the process of perfect, made-to-fit custom packaging delivered in-spec, in-budget and on-time…every time.

Covenant Packaging is Kansas City’s hometown corrugated partner for a world-class experience. Contact us today for perfectly measured, made-to-spec packaging.